An optimal amount of fluoride can improve the friction and wear performance of Ni3Al matrix high-temperature self-lubricating composites, according to a study carried out by researchers at the State Key Laboratory of Solid Lubrication.

Researchers first fabricated the self-lubricating composites Ni3Al–BaF2–CaF2–Ag–Cr, which have varying fluoride contents by the powder metallurgy technique. Through the study on the effect of fluoride content on the mechanical and tribological properties of the composites, an optimal fluoride content and a balance between lubricity and mechanical strength were obtained.

It was found that the Ni3Al–6.2BaF2–3.8CaF2–12.5Ag–10Cr composite showed the best friction coefficients (0.29–0.38) and wear rates (4.2×10-5–2.19×10-4 mm3 N-1m-1) at a wide temperature range (room temperature to 800℃). Fluorides exhibited a good reduced friction performance at 400 and 600℃. However, at 800℃, the formation of BaCrO4 on the worn surface due to the tribo-chemical reaction at high temperatures provided an excellent lubricating property.

The work has received support from the National Natural Science Foundation of China (NEFC) and Innovation Group Foundation from NSFC.

The findings have been published in Tribol Lett (Tribol Lett (2011) 43:341–349).

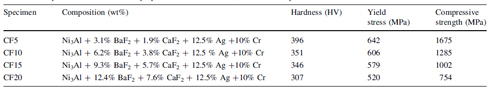

Compositions and mechanical properties of the sintered Ni3Al matrix composites