Graphene, as the building block of the most common macroscopic solid lubricant graphite, also exhibits excellent friction reduction and wear resistance properties and is expected to find broad potential applications in micro/nano-devices, which usually require strict requirements to the scale and performance of the lubricant films. The prerequisite of realizing the excellent performance of graphene in micro/nano-devices is to deposit graphene thin films on different substrates. Therefore, it is highly desirable to develop facile and feasible methods for preparing graphene films that can resolve the above problems.

Researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have designed a simple and feasible self-assembly route for the in-situ formation of graphene films using an adhesive PDA coating acting as both an active platform and the reducing agent.

|

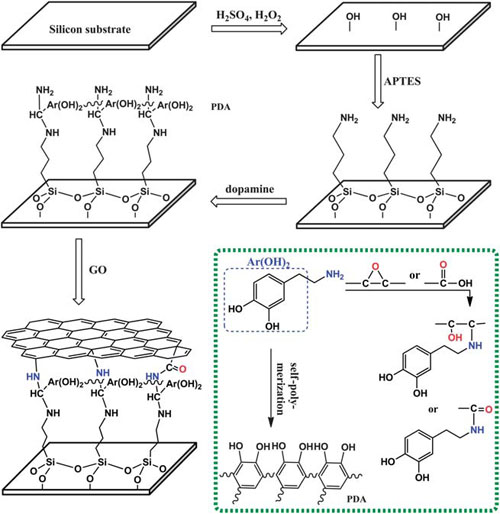

| Proposed schematic view for the assembly of APTES-PDArGO film on a silicon wafer (inset shows the main chemical reactions occuring in the process). |

The microstructure and tribological performance demonstrate the as constructed 3-aminopropyl triethoxysilane (APTES)- polydopamine (PDA)- reduced graphene oxide (rGO) film possesses excellent surface morphology, friction reduction and wear resistance properties compared with other samples. This simple and feasible approach offers a new route for assembling rGO films onto various substrates with various shapes and will find potential application in many fields such as nanoelectronics, sensors, nanocomposites, batteries, supercapacitors, hydrogen storage, and so on.

This work is supported by the National Natural Science Foundation of China . The findings have been published in J. Mater. Chem.(J. Mater. Chem., 2012, 22, 8036–8042).