The increasing demand for good thermal and/or electrical conductivity in friction materials has led to the quest for polymeric materials with comprehensive properties. Previous work has shown that various methods are used to improve thermal and/or electrical conductivity of polymer matrices. However, it is complicated to balance and optimize the mechanical, frictional, thermal, and/or electrical properties of such materials.

Researchers at Nanjing University of Aeronautics and Astronautics and Lanzhou Institute of Chemical Physics (LICP) of the Chinese Academy of Sciences (CAS) have developed a copper foam–based (CFB) self-lubricating composite as a friction pair material. The CFB composites showed a slight improvement in bending properties compared with those without copper foam and exhibited outstanding thermal and electrical conductivity due to the interconnected metal skeletons embedded in the PTFE based polymers. The wear rates of CFB composites substantially decreased compared with those of the homologous polymers without copper foam, and the friction coefficients affected by the copper foam varied with load and velocity. MoS2 as the reinforcement lubricant at 25% content was found to achieve optimum tribological properties.

|

|

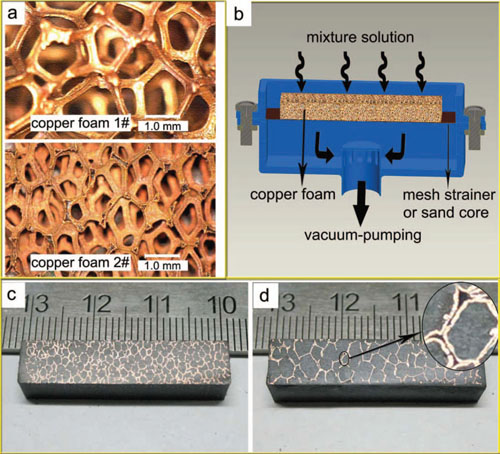

(a) Optical micrograph (50×) of two kinds of open-cell copper foam, (b) specimen preparation, and (c) and (d) photos of the CFB composites (P/M25-1 and P/M25-2) showing surface morphology (P/M25: 75% PTFE + 25% MoS2; P/M25-1: #1 copper foam filled with P/M25 component; P/M25-2: #2 copper foam filled with P/M25 component). |

An investigation of the contact resistances indicated that the frictional interface layer had a higher resistance in the wear stage, when the contact resistance was relatively lower before and after the run. The main wear mechanism of the CFB composites was three body abrasion, caused and promoted by plastic deformation, abrasive wear, and fatigue spalling. XPS analysis results of the identifiable copper area in the transfer film showed that oxidation of MoS2 and Cu and the reactions between them to form new compounds were the dominant chemical processes that occurred. The wear debris on the contact surface included copper debris (oxides included),MoS2 debris (oxides included), and PTFE debris.

The work has received support from the National Natural Science Foundation of China and the State Key Laboratory of Solid Lubrication at LICP.

The findings have been published in Tribology Transactions(Tribology Transactions, 55: 20-31, 2012).