Polyetheretherketone(PEEK) is increasingly used in tribological components because of its excellent performance such as high mechanical properties, good wear-resistance and heat-resistance, and excellent chemical resistance, etc.. To further improve the wear-resistance of neat PEEK and facilitate its application, many researchers made great efforts to develop PEEK-based composites by mixing appropriate additives into PEEK matrix. However, these studies mainly concentrate on the field of dry friction and pure water lubrication. The reports on the tribological behaviors of CF/PEEK under sea water environment have been hardly acquired so far.

|

|

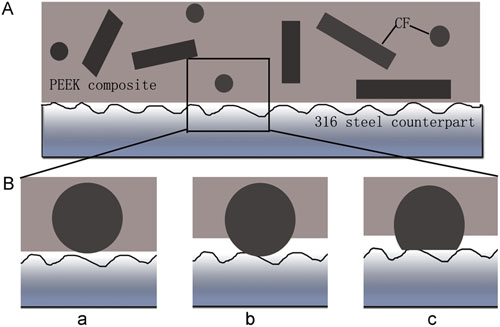

Schematic illustration of the reinforcement effect of CF on PEEK matrix during the process of friction and wear |

Researchers at State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), have prepared carbon fiber(CF) reinforced polyetheretherketone(PEEK) composites and comparatively investigated their tribological behaviors under sea water lubrication.

The results showed that the incorporation of CF can greatly improve the wear resistance of PEEK under sea water lubrication, especially when the volume fraction of CF was about 10%, because exposed CF can effectively share the main load between the contact surfaces and consequently protect the matrix from severe wear. In addition, CF/PEEK had better friction and wear properties under sea water lubrication than under dry friction and pure water lubrication due to better lubricating effect of sea water.

The work has received support from the National Nature Science Foundation of China and the National High-Tech Research and Development Program of China. The findings have been published in Tribology International(Tribology International52 (2012) 170–177).