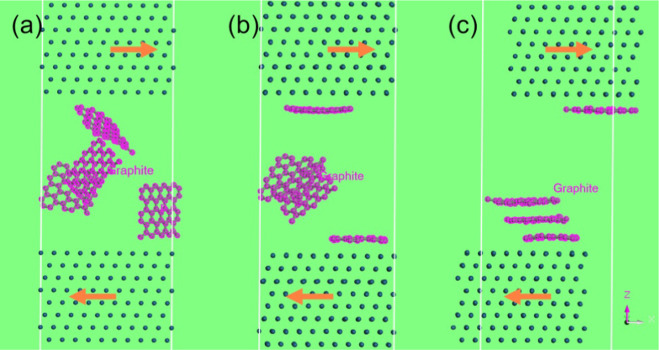

Abstract: The productions of self-lubricating alumina-graphite composite coatings were prepared through onestep plasma electrolytic oxidation in an appropriate graphite-dispersed electrolyte solution, and the microstructure, composition and phase constituents were examined. The friction and wear properties were investigated by sliding the disk samples against Si3N4 balls under dry and deionized water conditions, respectively. Molecular dynamics simulations about the interface states of graphite were also carried out to assist in the evaluation of the self-lubricating and wear-resistant mechanisms, making up the weakness of the conventional experimental method in microscopic study. The results indicated that the oxidation coatings greatly improved the wear resistance of pure aluminum. Further improvement in the wear resistance was achieved by self-lubricating of solid lubricant in oxidation coatings. In wear process, the wear debris aggregated together on the worn surface and the graphite particles formed layered structures, which exhibited excellent self-lubricating behavior and decreased the shear stresses generated by the moving stylus.

KeyWords Plus: MICROARC OXIDATION; TI-6AL-4V ALLOY; GRAPHITE; NANOCOMPOSITES; PERFORMANCE

Published in TRIBOLOGY INTERNATIONAL, 97 97-107; 10.1016/j.triboint.2016.01.020 MAY 2016