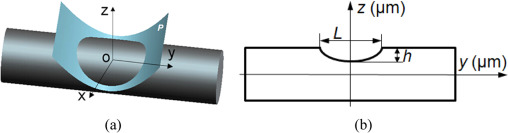

Abstract:Dynamic wear evolution and crack propagation behaviors of steel wires during fretting-fatigue were investigated in this study. Wear scar and wear depth profiles of steel wires were quantitatively analyzed employing a three-dimensional white light interferometer. Theoretical models of maximum wear depth and wear coefficient of parabolic wear scars were established. Three-dimensional crack propagation characteristics of steel wires were presented using X-ray computed tomography. The results show that larger fatigue cycles induce decreased increase rates of elliptical wear scar area and parabolic wear depth of steel wires. An increase of relative displacement induces reduced damage and thereby better anti wear properties of wires. The central zone of wear scar exhibits larger crack depth and faster crack propagation as compared to edge zones.

KeyWords Plus:FINITE-ELEMENT-ANALYSIS; HOISTING ROPE; PREDICTION; INITIATION; FRICTION; GROWTH; MODEL

Published in TRIBOLOGY INTERNATIONAL, 101 348-355; 10.1016/j.triboint.2016.05.003 SEP 2016