Triboelectric electrification is a common phenomenon in interfacial friction, in which electrons are continuously transferred, excited, and flowed between two surfaces. Most of the current research on the relationship between triboelectrification and friction force is based on contact resistance (friction between metal and metal), surface potential (mainly for dielectric), current and voltage to ground (friction involving metal friction pairs), and other test methods, ignoring the relationship between carrier transfer and friction at different interfaces that require different energy values for processes such as electron excitation. The triboelectric mechanism of superlubric friction interfaces at the macroscopic scale remains an unexplored area of tribology. Furthermore, triboelectric-based energy harvesting devices require tribological design to avoid device failure. There is an urgent need to apply antiwear materials to solve the tribological problem in triboelectric energy harvesting devices.

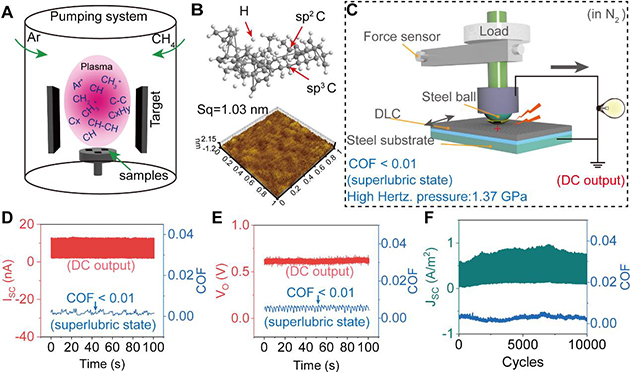

Prof. WANG Daoai’s group from the State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, has devised a new macroscale superlubric triboelectricity harvesting device. It can withstand high-contact stress with ultralow coefficient of friction (COF) (<0.01) and ultralow wear rate based on a hydrogenated diamond-like carbon (DLC) film from the tribological perspective (Figure 1).

Specifically, the device produced an output with the peak short-circuit current of approximately 60 nA and a power density of up to 5.815 W/m2 during the friction of DLC versus steel ball with a Hertz contact stress of 1.37 GPa. Moreover, first-principle calculations demonstrate that the ultralow friction on DLC is mainly due to the hydrogen-terminated surface. The device can generate direct current (DC) output caused by tribovoltaic effect and can light up several LEDs without rectification.

Figure 1. Concept display and schematic diagram of the macroscopic superlubric triboelectricity harvesting device.

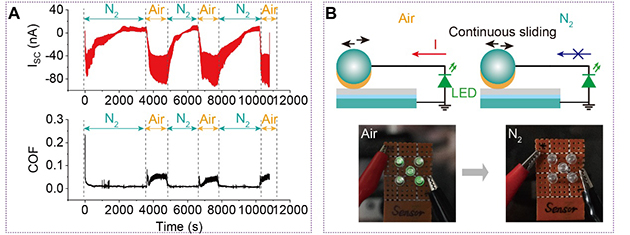

In addition, this work also realized the sensing of friction state based on the close correspondence between tribology and triboelectricity. In many cases, the information in the friction process reflected by the friction force curve is too little to reflect the friction state of the friction pair well. Thus, real-time sensing of the friction state is extremely important in tribology, which is helpful to understand the state of the friction pair and ensure the normal operation of the friction. Therefore, it is necessary to combine other test methods to characterize the friction interface state globally. The triboelectric signal is closely related to the friction state. Using the change of the electric signal to monitor the friction state is a very suitable and important means in friction sensing. The friction state in situ during the actual sliding should be grasped to maintain the safe operation of the machine and handle possible failures. If the atmosphere was repeatedly changed, then the friction current would change with the modification of the COF, and this repetition process is sensitive (Figure 2). This situation allows the current in the friction process to be used to detect the friction state in situ.

The above method can even be used to sense other frictional conditions, such as when certain objects (e.g., oil andwater) that have a negative influence on normal friction in the actual application are present at the interface.

Figure 2 Superlubrication state failure monitoring based on triboelectric signals and external circuits.

The research was also guided by Dr. Yufeng Guo (Nanjing University of Aeronautics and Astronautics), Wanlin Guo (Nanjing University of Aeronautics and Astronautics (NUAA)) and Zhong Lin Wang (Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences (BINN, CAS)). Dr. Liqiang Zhang (LICP, CAS), Haifang Cai (NUAA) and Liang Xu (BINN, CAS) are the co-first authors of the paper.

Relevant research was published in MATTER (DOI: 10.1016/j.matt.2022.02.021) and supported by the National Natural Science Foundation of China, the Key Research Program of the Chinese Academy of Sciences, the National Key Research and Development Program of China, Taishan Scholars of Shandong Province, the Innovation Leading Talents Program of Qingdao, the Fundamental Research Funds for the Central Universities of China, a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Contact:

Daoai Wang

Email: wangda@licp.cas.cn

Lanzhou Institute of Chemical Physics